CII takes centre stage at the 2022 Hull Performance and Insight Conference (HullPIC)

It may not be the biggest, or most well-known conference in the maritime annual events calendar, but for those working in any fields that focus on ship underwater hulls the annual Hull Performance and Insight Conference (HullPIC) is the place to be.

Now at its 7th edition, this conference regularly gathers 100+ participants and the attendee list packs a punch. Part of the charm of HullPIC is that it attracts a hearty mix of ship owners and operators matched with an equal number of technology and service providers. Interestingly, the conference is always set in slightly obscure locations that, although a bit of time and travel away from the airport is required, the conference always provides intimate setting for a meeting of minds and great networking.

Having owned a maritime events and publishing company previously, I must take my hat off to the conference organisers, DNV and Jotun. In particular, Dr. Volker Bertram of DNV who orchestrates the event every year. The way the event is hosted enables everyone to mingle and become acquainted very quickly. It’s evident that the voicing of opinions is encouraged, there’s a rotating panel of experts moderating the conference, not just one chairman and a real sense that anyone can ask a question, no matter how simple, or controversial it may be.

The HullPic conference room, full of enquiring minds

This year, we all flew into Dublin airport and took a train ride from the east coast of Ireland to a town called Tullamore located in the middle of the gloriously green country. The three-day agenda spanned hull performance optimisation, data, antifouling coatings, hull cleaning and emerging innovations. Participants, myself included and our Technical Director, Dr. Markus Hoffmann, relished in the opportunity to look ahead at innovations we can expect to take off in the next few years. For us, insights into antifouling coating developments and progressions are of most interest since this is the field in which we are most active with our antifouling ingredient technology, Selektope®, but it was also great to get a sense of what’s looming under the water line in terms of breaking technology and services.

Upcoming IMO energy efficiency measures took centre stage at the conference, and I would even go as far to say, the Carbon Intensity Indicator (CII) was the star of the show. Since the IMO laid down the rules for the incoming Energy Efficiency Existing Ship Index (EEXI) and CII, due to enter into force in January 2023, the industry has been awash with talk of how ratings will be calculated, and what its impact will be on ship operators and how CII ratings might influence chartering decisions.

Different to the Energy Efficiency Design Index (EEDI) which has been in place for many years already for newbuilds, and the incoming EEXI rules, the CII is an operational measure of a ship’s carbon emissions per tonne/mile. Under the new CII rules, ships will be given a rating between A-E, with A representing those with the lowest carbon emissions. The operators of any ships that receive a D or E rating must submit plans that detail how that ship’s poor performance will be improved and that will be audited through the ship’s Ship Energy Efficiency Management Plan (SEEMP). The plan for improvement must be approved by class societies and will be subject to company audits. Yikes.

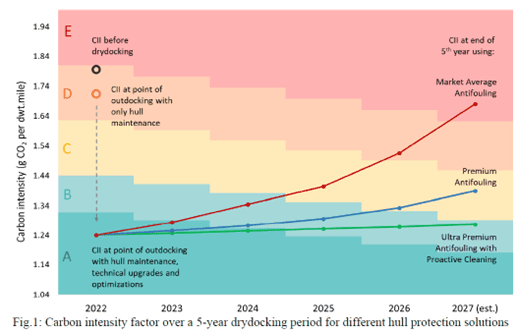

Since the CII is an operational indicator, biofouling on the hull can have a big impact on a ship’s rating, as can the presence of other clean technology, or not. This means an owner’s choice of antifouling coating for a ship will play a huge part in how a ship is rated, and how its rating plays out over its 5-year dry docking interval.

At HullPIC, the numerous ship operators in the room seemed quite confident that their ships achieve good ratings thanks to the technologies they have adopted. Of course it can be assumed that those attending the HullPIC conference were on the more proactive and environmentally conscious side of the scale in the industry, perhaps.

However, one thing was clear, anxiety does exist as to what ratings will actually be achieved, how the ratings will be calculated in reality and how ratings will change as the rating lower limits get stricter progressively from 2023 to 2026. There’s no quick fix to improving ratings if they do slump or are low to start off with and this is worrying.

When it comes to improving EEXI and CII ratings there are a few obvious candidates that were discussed at great length during this particular conference. Engine Power Limitation as a measure for older ships designed with higher speeds in mind for achieving EEXI targets is being put in the spotlight as a cost effective solution and it is assumed that many will adopt this. Shaft Power Limitation (ShaPoLi) and the ability of remote propulsion control systems to limit a ship’s shaft power output when the pre-set limit is reached, thereby helping operators to keep control of their vessel’s level of emissions in operation, was also discussed as a solution.

2022 Particpants

One thing is for certain - when it comes to CII ratings, the impact of biofouling on the hull should not be underestimated. This was a popular discussion topic amongst conference participants. Equipping a ship with a premium antifouling coating that is suited to the vessel type, speed and trading pattern, and not forgetting idling risk, is essential. If an antifouling coating that is less than premium, proactive hull management is essential, namely the cleaning or grooming of the hull surface to regularly return he hull to being completely free from biological matter and organisms. However, if you are unlucky enough to gather hard fouling species on your hull such as barnacles, this is where you might become a bit unstuck, or not (excuse the pun) since soft cleaning methods won’t usually shift glued on, hard-shelled beasties.

On a general note, there is huge room for improvement where hull condition is concerned, particularly when the global fleet is facing worsening conditions in warming waters thanks to global warming. Fouling species will continue to flourish in coastal waters as water temperatures creep up, just where ships sit at anchor in ports or just outside of ports or waiting for spot charter.

Periodic hull cleaning temporarily restores performance eroded by soft fouling however, the best proactive protection strategy, in my humble opinion, is to invest in a premium antifouling coating, that provides protection against biofouling for the entire 5-year drydocking interval. To go one step further, antifouling coatings designed to withstand attack from hard fouling species during extended idling periods in waters above 15oC are even better. With these types of coating on the hull operators can be safe in the knowledge that whatever is lurking under the waterline, in whatever waters the ship is idling, can’t attach to the hull and erode hull performance when the ship is back sailing.

Extended idling protection against barnacle fouling is an essential feature of antifouling coatings that is enabled by the presence of Selektope in the coating, but we won’t go too far into that here, I promise.

But I will share a small insight into our HullPIC presentation, which communicated our novel research into idling rates across the global fleet over the past ten years and how we quantified the true scale of the barnacle fouling issue worldwide. Dr. Hoffmann from the I-Tech camp voiced to HullPIC participants that the overwhelming evidence from our studies points to the hard fouling problem is only going to escalate in years to come and adequate protection is needed for ships with risk of idling in intensive barnacle fouling areas (in waters above 15oC) for periods longer than 14 days. The I-Tech presentation was well received, not surprisingly we usually provoke debate and discussion, interest and intrigue about our nano technology that prevents barnacle fouling by making the creatures swim away unharmed. If you want to read more about our studies, you can access our full HullPIC conference paper with all research insights included, here.

Dr. Hoffmann presenting for I-Tech

The bottom line is that hull coatings will have a significant impact on CII. This was reinforced by the Jotun team attending the conference. In his speech, Sergiu Paereli of Jotun stressed that antifouling coatings are essential in mitigating the impact of EPL on vessel speed and minimising the increase in a vessel’s CII rating. Essentially, a low performing antifouling coating could mean the difference between ratings since the presence of biofouling on the hull that drives down ship performance and drives up emissions, can negate the effect of other clean technologies onboard, he said. The presentation of simulations Jotun has run, supported by vessel performance data analysed using the ISO 19030 standard, confirm this.

The Jotun simulations showed that if a premium antifouling had been selected for their simulation vessel instead of a market average antifouling, the vessel’s CII rating would have stayed within the bands of A, B and C throughout the service interval. Proactive cleaning of the hull, enabled by recent developments in robotics, in combination with an ultra-premium antifouling, would enable an almost flat development curve, with the slight gradient attributed primarily to inevitable mechanical damages caused at berthing. However, for the vessel with the market average antifouling that started at an A rating, by year four that vessel is fast progressing into D rating territory and it only gets worse by year 5.

You can read Jotun’s full HullPIC paper, inclusive of the simulations here (page 190-197) or read an interesting article that they recently published that presents the simulations here.

Source: Jotun HullPIC paper, see hyperlink in text below.

Moving onto data. A huge part of the HullPIC conference this year was data-focussed, again reflective of a hot industry discussion topic. The power of monitoring and data was examined across various sessions of the conference and how better data insights lead to better decision making.

CFD, towing tanks and the quantification of energy saving across different hull and propeller technologies were also popular topics. AI and AI-modelling even made an appearance, and we were treated to insights into the benefits and challenges of machine learning for ship performance modelling and details of the various collaborations in this fast-advancing arena.

I found the conference session that I chaired with Ditte Gundermann, Senior Engineer at Hempel, particularly interesting, especially that of Solene Guere, from French company Notilo Plus. This company uses advanced aquatic drone and a comprehensive online data platform to conduct remote and thorough hull inspections. They can map biofouling on the hull of a ship in square metre sections, allowing for more targeted, and quicker more cost effective cleaning. The whole hull is displayed on a dashboard, colour coded by intensity of fouling and this allows for targeted cleaning. This could potentially save time and money during any necessary hull cleaning activities.

When it comes to sHip owner and operators’ viewpoints on CII, discussion centred around the impacts on vessel chartering. In one panel discussion, Martin Köpke of Hapag-Lloyd expressed his belief that charter contracts will change. He believes that there will be a clause in the time charter party contract that will take into account the CII rating. BIMCO’s Aron Sorenson confirmed that they are in fact developing a CII compliance clause for time charter parties. Watch this space, apparently it is due any time now.

In addition to the conference presentations and resulting discussions, an opinion survey conducted by Idealship revealed that the ship owners/operators in the room have started preparations for complying with EEXI, and the majority of survey participants said they are almost ready to meet it.

Over 50% of HullPIC delegates voted for the application of high performance paints at drydocking when asked how shipping companies will mostly improve vessel efficiency in the next three years. When asked how the CII will predominantly impact the chartering market, almost 60% of delegates said that charter parties will be more transparent and over 20% of respondents voted for the option that charterers will only hire vessels with A-C ratings. While this is only a small sample, the company types and roles are vast at this conference so, even this small survey serves as a very useful indicator of industry opinion.

The HullPIC conference is one that industry representatives return to year-on-year and after my inaugural year of attending, I can see why. It’s an industry conference that actually achieves having a big number of ship operator participants in the room, expressing their knowledge and opinions with a good mix of technology developers and service providers. The conference locations are unusual but charming and the insights are invaluable. Until next year, HullPIC.

Related articles

Innovative Solutions and Global Collaboration: Highlights from the 3rd GloFouling R&D Forum in Busan

Take aways from IMarEST Biosecurity Symposium 2024

Navigating innovation for smooth sailing: A recap of SMM 2024