I-Tech and LANXESS unlock novel antifouling biocide combinations through R&D partnership

As the maritime industry faces increasing biofouling risk below the waterline, the novel combination of existing, approved antifouling solutions is essential for ensuring that today’s antifouling coatings meet tomorrow’s biofouling challenges.

I-Tech AB, the developers of the antifouling biotechnology, Selektope® and global specialty chemical company, LANXESS have successfully combined their respective antifouling technologies for the first time with promising results.

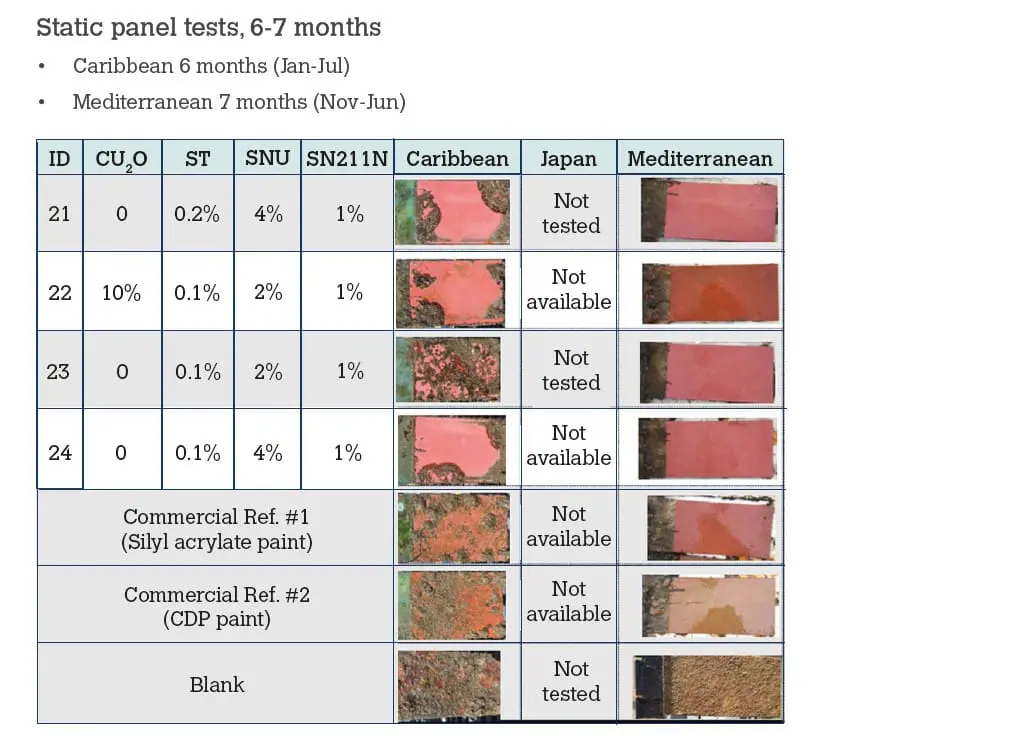

Static tests of antifouling coating formulations containing Selektope and the SEA NINE™ family of biocides were conducted in multiple marine environments worldwide with differing biofouling risk. Positive results obtained have provided proof of concept. Additionally, a data pool of coating formulations has been developed that can be used by antifouling coating manufacturers to support the trialling of new combinations of existing, available biocides without the need to conduct initial R&D exploration activities.

Antifouling coatings are the first line of defence against biofouling accumulation on ship hulls and niche areas. Continuously protecting the underwater surface of a vessel that can have changeable operating patterns and transits in and out of varying biofouling risk zones for up to five years is very tricky.

Coating systems that make use of biocides are the most common type utilised today. However, the number of approved biocides available to paint manufacturers has significantly decreased during the past decade. Therefore, finding new ways to combine existing biocides is essential. Collaborative R&D efforts between biocide suppliers play a key role in supporting the optimisation of future antifouling coating technologies by providing proof of concept and initial R&D findings. This can enable coating manufacturers to fast track product development and improve antifouling performance.

I-Tech’s technology, Selektope® and LANXESS’ technologies, SEA-NINE™ 211N and SEA-NINE™ ULTRA belong to a rare set of active agents that are approved by regulatory bodies in leading nations for ship repair and ship building markets. This joint R&D work undertaken by I-Tech and LANXESS represents the first time that these solutions have been used as co-biocides in marine antifouling coating formulations.

Selektope® is an organic, non-metal biocide that prevents hard fouling. It repels barnacle larvae from a coated surface with non-lethal effect using a novel, biotechnological approach achieved by the active agent medetomidine. Through natural receptor stimulation, the swimming legs of barnacle larva kick at a higher frequency so that they cannot attach to the coated surface.

The LANXESS SEA-NINE™ family is based on the active substance DCOIT which has a broad anti-microbial activity spectrum with a special emphasis on soft fouling prevention. SEA-NINE™ 211N contains 30% DCOIT. It was launched in 1986 and is used in many premium coating products. LANXESS will commercially launch a new marine antifouling agent under the SEA-NINE™ product family in 2023. SEA-NINE™ Ultra contains 80% DCOIT in a rigid core-shell encapsulation format to ensure controlled delivery of the biocidal active agent DCOIT during the antifouling service life.

For the past twelve months, I-Tech and LANXESS have worked together to develop active ingredient compositions that comprise varying concentrations of Selektope®, SEA-NINE™ 211N and SEA-NINE™ ULTRA with other commonly used ingredients for marine antifoulant applications. Thirty-five paint formulations with a twelve-month lifespan were developed and put into static testing environments in the Caribbean, Eastern North Sea, North Mediterranean and in the Japanese Sea.

After six months all test paint formulations had performed as good, or better than, the commercial paint references. Formulations with SEA-NINE™ ULTRA (2%) and Selektope® (0.1%) content showed excellent performance at reduced total biocide concentrations.

Dr Markus Hoffmann, Technical Director at I-Tech comments: “This year the I-Tech R&D team is harvesting the results from many successful collaborative projects undertaken with fellow antifouling technology developers. We believe this is the only way forward when trying to ensure that our technology helps the maritime industry to tackle increasing biofouling issues. Biocidal antifouling coatings are here to stay and at I-Tech we are invested in ensuring that the technology available now can be used to best effect in the future by proving performance across as many different potential application scenarios as possible.”

Related articles

Reflections on 2025 – by Markus Jönsson, I-Tech CEO.

I-Tech and Havey sign MoU to collaborate on the development of next-generation antifouling materials

Stellar group of antifouling experts selected to guide 2025 International Antifouling Conference through “Investigating Sustainable Antifouling Solutions”