Incorporating Selektope®(medetomidine) into silicone-based foul release coatings

To-date, the marine biocide, Selektope (medetomidine) has been successfully commercialised in multiple self-polishing biocidal coating products for its function of repelling barnacle larvae from underwater hulls to prevent settling behaviour.

This barnacle repelling effect is achieved when medetomidine leaches out from the coating surface when it is continuously polished by seawater.

Currently, the use of medetomidine in foul release coating types has not been commercialised.

However, extensive R&D work has been undertaken by I-Tech to investigate concepts for incorporating medetomidine into foul release coatings (FRC). The concept of incorporating medetomidine into silicone-based foul release coatings through the reaction of medetomidine and a functional isocyanate group on silicones has been successfully proven.

This work builds on previous demonstrations, as reported in literature, that medetomidine can react with (trialkoxysilyl)alkyl isocyanate.

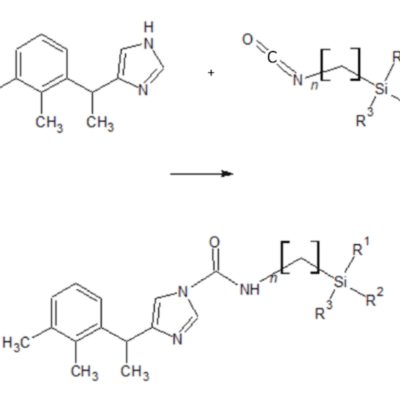

The first concept tested by I-Tech for the incorporation of medetomidine into silicones involved the use of (trialkoxysilyl)alkyl isocyanate as a reactant for creating an adduct between medetomidine and the silicone network through the isocyanate and alkoxy groups in the (trialkoxysilyl)alkyl isocyanate. After reacting medetomidine with (trialkoxysilyl)alkyl isocyanates, the reaction product can be integrated in silicone coatings based on the alkoxysilane-silanol cross-linking chemistry. (See Figure 1 below).

Figure 1. Medetomidine attached at the ends of a (trialkoxysilyl)alkyl isocyanate through the reaction with the isocyanate group. The hydrolysis of the formed urea bond results in the release of medetomidine. R1, R2 and R3 are any alkoxy group.

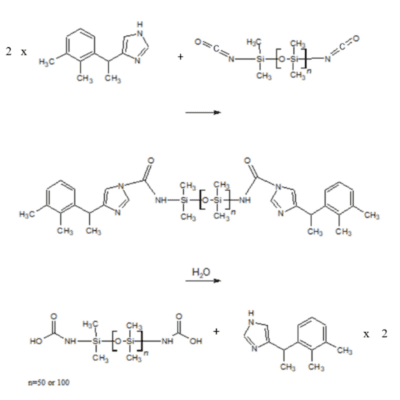

The second concept tested by I-Tech for the incorporation of medetomidine into silicones involved reacting medetomidine with isocyanate functional PDMS. It has been shown that medetomidine can be covalently attached to PDMS by forming isocyanate adducts, which is a method for incorporation of medetomidine into silicone coatings.

In this test, a linear di-functional isocyanate silicone pre-polymer, polydimethylsiloxane (PDMS) was reacted with medetomidine in an inert solvent (Dowanol PMA) to incorporate medetomidine at the end of the PDMS chain (see Figure 2 below). The medetomidine can thereafter be released from the silicone network through hydrolysation upon contact with sea water.

Figure 2. In the first step of the reaction, PDMS with isocyanate at the ends reacts with medetomidine causing them to covalently attach. In the second step, the medetomidine terminated PDMS is hydrolysed and the medetomidine is released.

ATR-FTIR (Attenuated Total Reflectance Fourier Transform Infrared) spectroscopy was used to study the reaction of isocyanates attached to the PDMS, by analysing the absorption peak of the isocyanate-stretching vibration that is around 2275-2250 cm−1.

The recent R&D work conducted by I-Tech confirms two new approaches of integrating medetomidine into silicones. There is still work to be done in this field, which is needed and ongoing.

The next step will be for I-Tech to study the incorporation of the medetomidine-PDMS adduct into silicone coatings in detail. This can be done either by adding a fully reacted medetomidine terminated PDMS oil, free from reactive isocyanate groups, or by adding an isocyanate functional PDMS oil where parts of the isocyanates have been reacted with medetomidine and the remaining isocyanate groups can react with, for instance, free silanols in the silicone paint.

The medetomidine-containing silicone paint will then be applied onto test panels and immersed in seawater to test the release and antifouling performance of the medetomidine-containing silicone-based coatings prepared with the novel method described above.

More details on the approaches taken by I-Tech and the results obtained can be found in the full paper that describes this R&D work. Click here to download the full technical paper

Related articles

Innovative Solutions and Global Collaboration: Highlights from the 3rd GloFouling R&D Forum in Busan

Barnacles: Invited or Invader?

Exploring the Diversity and Resilience of Barnacles!