The successful journey of Selektope: From lab to hull powered by entrepreneurial spirit and science

The challenge

The biological complexity of the phenomenon we call biofouling is enormous. Each biofouling organism has its own solution for how to find and stay firmly attached to a surface, which they have evolved over millions of years.

Our area of expertise is barnacles. We are barnacle mad at I-Tech and have some of the best minds in marine biology and chemistry working with this biofouling organism day in, day out.

Barnacles secrete a cement that is among the most powerful natural glues known – meaning they are incredibly hard to remove. The excess friction (hydrodynamic drag) they add to vessels’ hulls, could account for as much as 110 million tons of excess carbon emissions across the global fleet[1]- and an additional US$6 billion spent on fuel per year.

The first line of defence against barnacle fouling is prevention protection provided by antifouling coatings. If they do attach, they can only be removed by removal techniques that damage the coating layer. Even then, often the barnacle’s base plate remains and continues to limit coating functionality. Therefore, a defence system build into the coating system is of highest priority. This can be achieved by achieving optimal biocidal loadings and/or combinations of biocides in biocidal coatings and foul release systems (so called silicone based system).

Our technology is one of the key biocides for preventing barnacle fouling. Since I mention that Selektope is classified as a biocide, it’s a good time to explore the journey that Selektope took from lab to hull, and the challenges faced that could have sunk us into the tech valley of death (spoiler alert: regulatory approval as a biocide in the EU was the main one).

[1] https://selektope.com/wp-content/uploads/2020/10/ITECH-WHITE-PAPER_June-2020-1.pdf

The beginning

Selektope began life in the Swedish Foundation for Strategic Environment Research (MISTRA) Programme for Marine Paint, a Swedish multidisciplinary research project at the University of Gothenburg and Chalmers University of Technology in the 1990s. The mission of this Marine Paint project was that it should not just generate fundamental research regarding antifouling substances, it should result in an actual product with the potential to reduce the environmental footprint of antifouling products on ships and leisure boats.

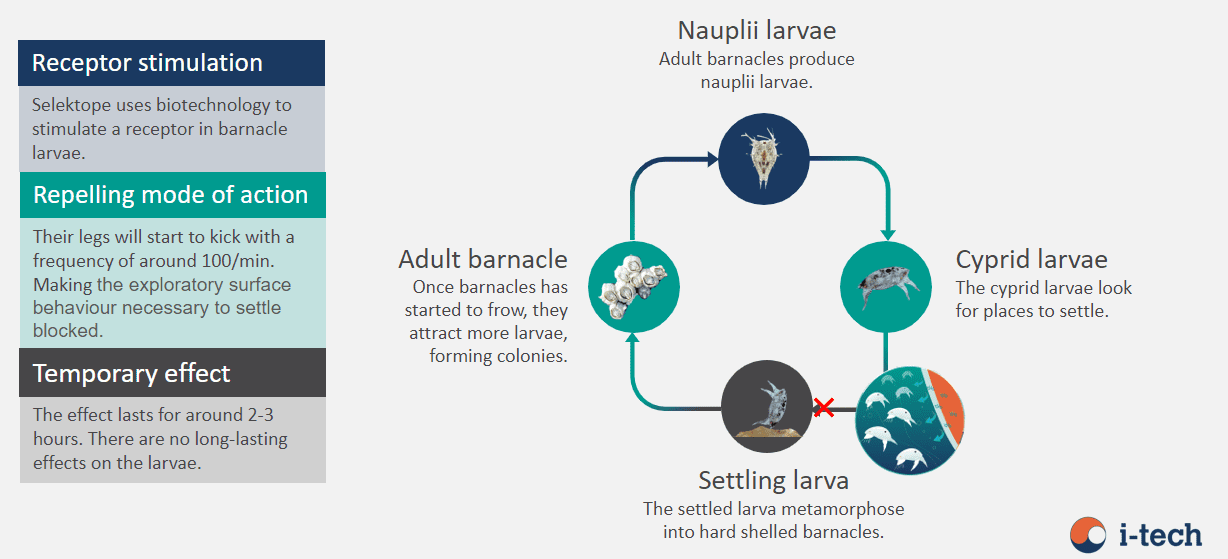

When studying a range of substances, scientists had an eureka moment with the substance medetomidine, a substance that is widely used for aesthetic effect in mammals. When exposed to medetomidine, leaching out from a wet coating, the cyprid larvae of the species Balanus improvisus were repelled from the coated surface, without lethal effect.

I-Tech AB (Interface Technologies) was founded (in 2000) to hold the patents filed by the founding researchers. The company was initially hosted by the incubator-branch of Gothenburg University. Shortly after, funding via grants and business angels took place where the most emphasised public funding came from MISTRA.

The first ten years of development much of the focus was spent understanding medetomidine as an active substance. Large efforts were made to gain insight into the substance’s mode of action on barnacles, and at which concentrations the substance was most efficient. The leaching behaviour of Selektope in paint and possible environmental risks of using Selektope commercially was also examined in great depth.

We knew it worked. However, while work in the lab demonstrated the desired kicking behaviour, the next question was: how do you know it works on an industrial scale and on the side of a 200-metre ship? This process took another twelve years to complete.

Turning medetomidine into a product that could be used by paint manufacturers was a challenging process, particularly for the time needed to get the regulatory certifications and permissions in place. The strategic decision was made by I-Tech to achieve regulatory approval of Selektope under the, at the time, newly implemented biocides legislation in EU - the Biocidal Products Directive 98/8/EC (BPD).

The regulatory landscape for new biocidal substances is extremely complex due to their effect on living organisms. This makes the development and commercialisation of biocides a very tough, and expensive, road to travel. The BPD was established to regulate the use of biocides and avoid the situation of any substances which could pose a risk for humans, or the environment being placed on the market. As such, the requirements for an application dossier under the BPD are extensive. Overall, we spent six years just trying to get relevant study data to be able to do a risk assessment on the molecule, solely on the environmental and the human exposure side.

In total, I-Tech submitted a dossier containing approximately seventy original studies on Selektope in 2009. By the end of the evaluation the number of studies had increased to ninety.

Also, the cost to develop a dossier for an EU approval application containing all the required information is in the range of 5-10 million euros in investment. However, without EU approval a new biocide is likely to never reach the market at all. However, we were lucky to have patient and strong owners supporting the company through the EU regulatory process. That, in combination with an existing toxicology data package from the substance approval as a pharmaceutical substance, made a large difference to the financial burden taken on by I-Tech.

In the end we made it through and that’s when the commercialisation of Selektope really began to speed up.

The arrival of ‘powered by Selektope’ onto the market

With BPR regulatory approval in hand, a full approval in Japan (CSCL & JPMA), Korea (NIER) and China (MEP, Order 7) and notifications in other relevant regions for shipping. this first-of-its-kind technology rapidly caught the attention of coatings suppliers. The first commercial Selektope-containing coating products for use on ocean going vessels were launched in the market in 2016 and since then over one thousand full applications of Selektope -containing antifouling coatings have been made on various vessel types.

Today, over twenty products that contain Selektope are on the market. Our largest customer, Chugoku Marine Paints (CMP) is the main contributor to the growth but recurring sales to five other large paint companies also contribute. Up-take in Japan is considerable and is linked to an increase of the many products launched on this market the past few years. Selektope is increasing its share in CMP’s Japanese product portfolio. Growth is also considerable in Korea with its strong position in the new building segment.

The future

Thanks to a continued stable financial position, clear investments have been made in our core business. Within the regulatory arena, geographical coverage is increased step-by-step at the same time as upgrades and renewals of existing approvals are required at regular intervals. We are also investing heavily in research and development in line with the strategy of offering a higher level of knowledge about Selektope’s formulation properties in antifouling coatings. The continuous improvement work has also led to an increased delivery capacity and efficiency in the production chain.

Ships are spending longer periods of time idle in coastal areas which intensifies the risk of barnacle fouling. The requirement to lower emissions from ships and improved ship efficiency imposed through international regulation is also creating a greater need for Selektope.

All of this is building a strong foundation for the continued expansion for Selektope use in the maritime industry and I’m glad to say that our team is just as passionate about the technology as they were twenty years ago.

The next step for I-Tech is for us to move to larger premises in late-April this year that will facilitate the expansion of our team and new laboratory facilities that will enable us to expand our already extensive R&D efforts. The future is looking very bright for Selektope!

Click here to read our Year End 2022 Report (released in February 2023)

Click here to read our Annual Report 2022 (released in April 2023).

Related articles

Innovative Solutions and Global Collaboration: Highlights from the 3rd GloFouling R&D Forum in Busan

Barnacles: Invited or Invader?

Exploring the Diversity and Resilience of Barnacles!