46,067DWT IMO II Chemical and products tanker – 5 years

A copper-free coating product containing Selektope® was applied to the side walls of the 2010-built, 46,067dwt IMO II chemical and products tanker vessel Calypso during its first five-year survey at the Singapore yard Sembcorp.

After a 60-month sailing interval, the Team Tankers-operated tanker, Team Calypso displayed an average weighted speed loss of only -0.7%. An underwater hull inspection reported almost a complete absence of hard fouling in any of the vertical sides or flat bottom of the hull, despite the vessel operating predominantly in some the world’s most severe biofouling hotspots.

A copper-free coating product containing Selektope was applied to the side walls of the 2010-built, 46,067dwt IMO II chemical and products tanker vessel Calypso during its first five-year survey at the Singapore yard Sembcorp.

Hydrodynamic analysis of performance data during the trial was carried out by independent party Propulsion Dynamics. Operating rates were measured by fuel oil consumption and power output.

Twenty-four months out of drydock, Calypso’s increased total resistance was calculated to be 7%, compared with a benchmark new vessel that would see an increase in resistance of 10-20%. This 7% increase in resistance corresponds to a mere 2% speed loss relative to sea trial performance. The increase in resistance from the propeller was 2%, with the remaining resistance being measured on the hull. Additionally, the independent analysis confirmed that the development rate of added resistance for Calypso is 0.1 % (normally 0.5% to 1.5% is expected).

The benchmark is made up of a wealth of different vessels with different coatings related to the size of the database within Propulsion Dynamics. This benchmark allows for the comparison of one ship to a large variety of similar vessels, thus addressing the problem case that it is not possible to compare equal ships to equal ships when analysing and contrasting coatings performance.

Latest News & Blog

Japan: where Selektope antifouling coatings bloom like the Sakura 桜 in Spring

20 tonnes of Selektope safeguards 2,500 vessels from barnacles

Biofouling: reflections from Kormarine 2023

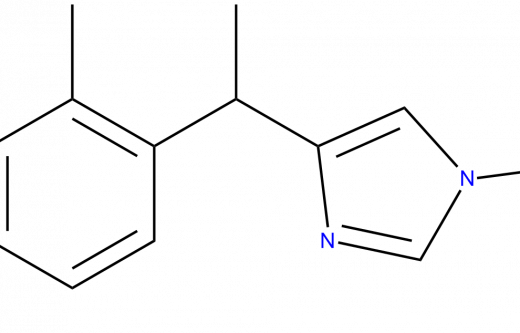

Incorporating Selektope®(medetomidine) into silicone-based foul release coatings

To meet decarbonisation targets, ships need effective antifouling systems now, more than ever

Industry collaboration is key to keeping hulls clean

The successful journey of Selektope: From lab to hull powered by entrepreneurial spirit and science

CII takes centre stage at the 2022 Hull Performance and Insight Conference (HullPIC)

Reflections on Nor-Shipping 2022

Insights from our time spent on the world’s Largest Hospital Ship

Looking ahead in 2022

Selektope cements itself in the shipping industry nine years since first introduction to antifouling coatings

For paint manufacturers

Push the boundaries of coating innovation.

For ship owners & shipyards

Unlock the benefits.